In-Mill Services

- Field Service for pulp bale, paper roll and secondary fiber systems. Typically covers maintenance, control system tuning and review of spare parts stocking.

- Engineering Services for feasibility studies, project definition packages and/or optimization efforts for pulp bale, roll wrapping and handling, as well as secondary fiber systems.

- System Audits to identify opportunities for efficiency improvement and safety enhancement. May be based on in-house review of Lamb Grays Harbor Co. records or combined with on-site evaluation.

- PLC Conversions to update obsolete control hardware and software platforms. Includes complete engineering and documentation as well as commissioning services.

- Training Programs for new and existing systems that are customized for each situation to maximize customer benefit. Programs typically utilize a combination of classroom and hands-on instructional methods.

|

|

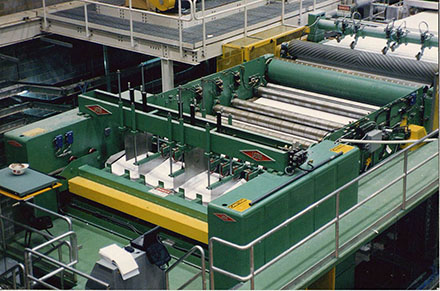

Pulp Bale Finishing

|

- Cutter-Layboy systems for processing a wide range of web widths, speeds and automation levels.

- Bale Handling and Wrapping systems, from stack formation through wrapping, tying, marking, stacking, unitizing and delivery to warehouse.Hogs

- Upgrades and retrofits to virtually all installed cutter-layboy and bale line equipment for enhanced performance, reduced operating cost and improved safety.

|

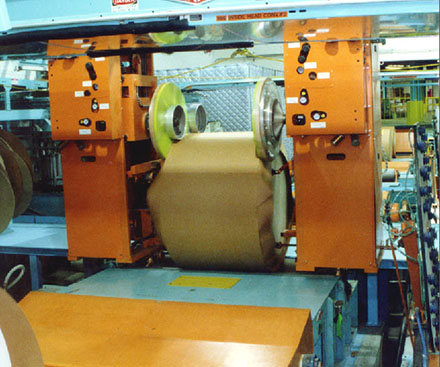

Roll Finishing

- Roll Handling equipment and controls for reliable transfer from winder to warehouse, including conveyors, elevators, ramp systems and vacuum truck attachments.

- Kraft Roll Wrapping equipment from identification through wrapping and labeling, covering a wide range of product sizes, production rates and automation levels.

- Upgrades and retrofits to installed roll finishing systems to provide enhanced performance, reduced operating cost and improved safety.

|

|

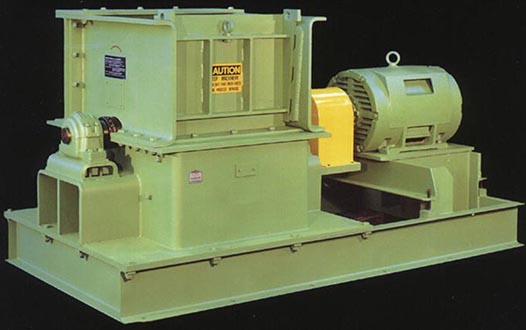

Bale Dewiring

|

- Recycled fiber and market pulp handling systems with controls for pulper charging. Highly effective automatic dewiring technology for waste bales with the Wirewolf Mark V dewiring station and the WireWolf MP-99 for market pulp dewiring.

- Upgrades and retrofits to existing fiber handling and dewiring systems to provide enhanced performance, reduced operating cost and improved safety.

|

| Pulp Cutter Layboys |

Hogs and forest products |

|

|

| |

|

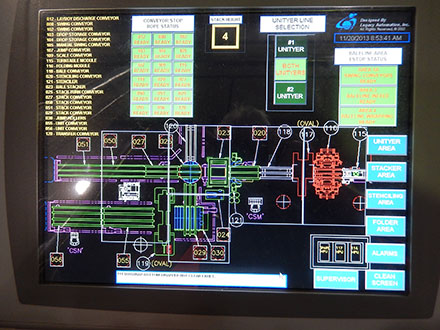

| PLC & Control Systems |

Safety Audits and Controlled Entry Systems

|

|

|

| |

|

Roll Vacuum Truck Attachments

|

In Shop Equipment Rebuilds

|

|

|

|

|

Pulp System Upgrades

|

Field Engineering

|

|

|

| |

|

Legacy Automation, Inc. is here to serve your needs, whether it be for new systems, improvement upgrades or Spare Parts and Field Service for existing Lamb Grays Harbor Co. equipment.